A class of specialty chemicals generally purchased as a base stock by commercial lubricant formulators and blenders to produce high-performance synthetic lubricants for sale into the aviation, automotive, locomotive, power, and industrial machinery sectors.

Fine Chemical R&D

OUR BROCHURE

OUR OFFICE

| Office No. 31, Bldg No.1575, Road No. 4631, Block No. 646, Al Nuwaidrat, Kingdom of Bahrain |

| (+973) 1721 1890 |

| info@mpaolab.com |

MPAO (Metallocene Poly Alpha Olefin)Fine Chemical R&D

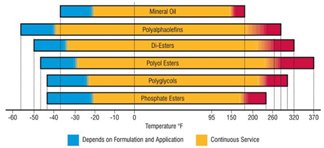

Physical Property Of MPAO

- Very Low Concentration Of Impurities

- Extremely Stable Molecule

- High Viscosity Index

- Low Pour Point

- Compatible With Other Base Stock Components & Additive Components

- High Ignition Temperature & Flash Temperature

- Low Vapor Pressure

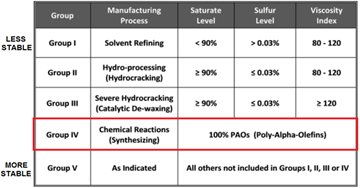

Characteristic Of MPAO (Comparing With Group I, II, III)

- Much Wider Viscosity Range

- Higher Viscosity Index

- Lower Temperature Fluidity

- Lower Volatility

- Better Oxidative /Thermal Stability

OUR SERVICE : R&D FOR MPAOAPPLICATION OF MPAO PROJECT

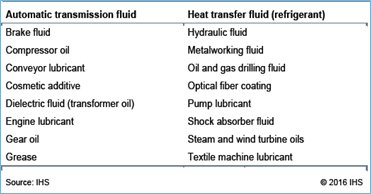

Application Of Lubricant From MPAO

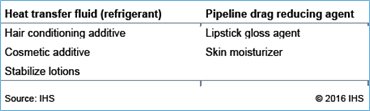

Other Application Of MPAO

Commercialize Product Brand From Poly Alpha Olefin (Synthetic Lube Oil)

- Mobil 1 & Mobil Super

- Castrol Edge

- Valvoline Synpower

- Shel Rotella

- Pennzoil

- Royal Purple

- S-Oil 7

- Amsoil

- Kixx Pao1

OUR SERVICE : R&D FOR MPAOABOUT METALLOCENE CATALYST

Metallocene Catalyst

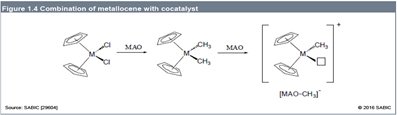

Metallocenes are the very effective metal catalyst that combines an organic framework with an active metal. Commercial metallocene catalysts generally use tow cyclopentadiene anions for the organic component, sandwiching the metal cation between them.

Metallocene Catalyst also is known as single-site catalysts because they have only one active site per catalyst particle, which are all identical.

Advantage of Metallocene Catalyzed Polymerization

- Like Ziegler‐Natta catalysts, allows control over PE structure (branching) and polymer tacticity

- Synthesis of ultra-high MW polyethylene

- High activity and ability to make coatings due to homogeneous nature H Advantages

- Single‐site catalyst – achieve low MW distributions (PDI<2)

- A wide variety of metallocene polyethylene can be produced with very different properties ranging from very soft with low meting point to high melting point with good heat resistance.

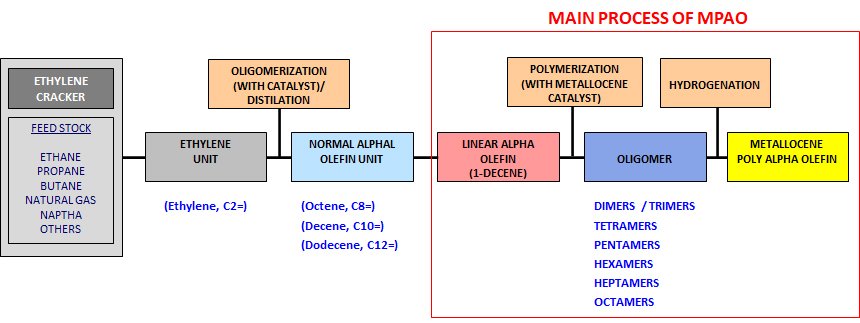

Process For Mpao Project

Status For Development Of MPAO Project

MAIN PURPOSE OF R&D FOR MPAO

- R&D for process of poly alpha olefin by metallocene catalyst

- Own Patent & Intellectual Property for process of MPAO

- Invite Investment for MPAO Plant by Feasibility Study

- FEED (Basic Engineering) work for MPAO

- Execution of 100 ton Pilot MPAO Plant in Saudi Arabia

- Execution of 50,000 ton Commercial MPAO Plant in Saudi Arabia

CURRENT STATUS

- Contract of R&D for MPAO Process with KRICT (Korea Research Institute of Chemical Technology

- Successful Experimentation for chemical process of MPAO in KRICT

- Successful Collaboration and lab-scale experimentation with KFUPM in their research lab

- International Patent for MPAO process

- Feasibility Study and Financial Projections

CONTRACT WITH KRICT & LOI KFUPM

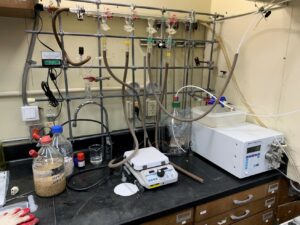

LABORATORY FOR R&D OF MPAO (IN KRICT)

KFUPM Lab Saudi Arabia